RITZ

RITZ - Ritzbrasil (Introduction) : Contend from RITZ Website

About RITZ Bresil

Ritz Ferramentas has specialized for over 55 years in the design and manufacture of tools and equipment for maintenance work on de-energized and energized electrical systems. We have a complete portfolio of tools for maintenance work on live lines up to 800 kV AC and DC for work on electrical systems in contact, distance and potential methods, meeting Brazilian, international and ISO 9001 standards.

Pioneer in the manufacture of live line tools in Brazil, it developed its first tubes reinforced with fiberglass for maintenance in energized networks in 1968, with the manufacture of the so-called Hot Sticks, as it already had a wide knowledge of this technology in the manufacture of insulating parts for application in small oil volume circuit breakers. In 1971, Ritz produced the first complete set of tools for maintenance on energized networks.

Between 1973 and 1989, the association with A.B. Chance Company, world leader in the segment. The association generated an exchange of know-how and process innovation, making Ritz recognized worldwide for its quality, safety, reliability and excellence.

In 2011, another new stage began for the company, with the acquisition by the North American multinational Terex. This provided an evolution and improvement in processes, methodologies, layout, technology, safety, skills, results and the conquest of new international markets.

In 2021, in line with the tradition and reference of the Ritz brand, the shareholding control of the company passed into the hands of a company formed by a group of managers from the predecessor Ritz Ferramentas, maintaining and strengthening the commitment to continue the trajectory of development and innovation that are important marks of its legacy.

QUALITY REFERENCE

RITZGLAS® glass fiber reinforced tubes, a Ritz trademark, are internationally recognized for their quality and reliability. RITZGLAS® tubes are subjected to tests based on ASTM F-711 and IEC 60855 standards.

RITZGLAS® Insulating Tube, a critical integral part of most Ritz live line tools, has a core of single-cell polyurethane foam internally, which prevents moisture or dirt from absorbing and condensation. Its external construction consists of highly treated glass fibers arranged in a circumferential and longitudinal direction and impregnated with epoxy resin of a special formulation.

RITZGLAS® tube has high dielectric strength, mechanical strength and low weight, essential characteristics for live-line tools.

The orange of the RITZGLAS® pole is suitable for its good visibility in the work areas, considered an additional safety item for the electrician team.

RESPONSIBILITY THAT CREATES VALUE

Specialized professionals, in permanent process of updating knowledge, dedicated to the elaboration of customized projects according to the needs of each client.

Our engineering department has the most advanced software on the market for the development of new solutions, 3D simulations and prototypes for validation in an agile and reliable way, reducing the time of approval and availability of the product.

SAFETY IN ALL STEPS OF THE PROCESS

Experience and technical excellence to carry out tests and inspections in accordance with NBR, ANSI, IEC and ASTM Standards, meeting the technical specifications of our customers.

Laboratory for electrical tests up to 400 KV and mechanical tests up to 75 tons, installed in an area of 500 m² with modern and calibrated equipment, adequate infrastructure with traceable and international standards that ensures that all products are released for use only after rigorous inspection and approval.

TO GROW AND EVOLVE TOGETHER

We believe in building a relationship of quality and trust with our customers, prioritizing service to Electric Energy companies (Generation; Transmission; Distribution), as well as their service providers throughout the national territory and in more than 60 countries.

INTRODUCTION PRECAUTIONS FOR HOT LINE TOOLS The hot line tools described in this catalog must be handled, installed, and stored only by trained personnel who are familiar with the operating procedures and in compliance with applicable safety standards. The information contained in this catalog and any other information in the instruction manuals shall under no circumstances replace proper training and experience in safety procedures. In addition, they do not cover all details on the tools, nor cover every possible situation concerning tool installation, operation, and maintenance. For further information or special requests not included in this catalog, Ritz should be contacted to assist in developing the most viable solution. Ritz Ferramentas is continually looking for ways to improve its products and services. Therefore, the information in this catalog may be changed without prior notice, always in view of the total safety of electricians involved in the maintenance activities in electrical systems.

HOT LINE WORKING METHODS

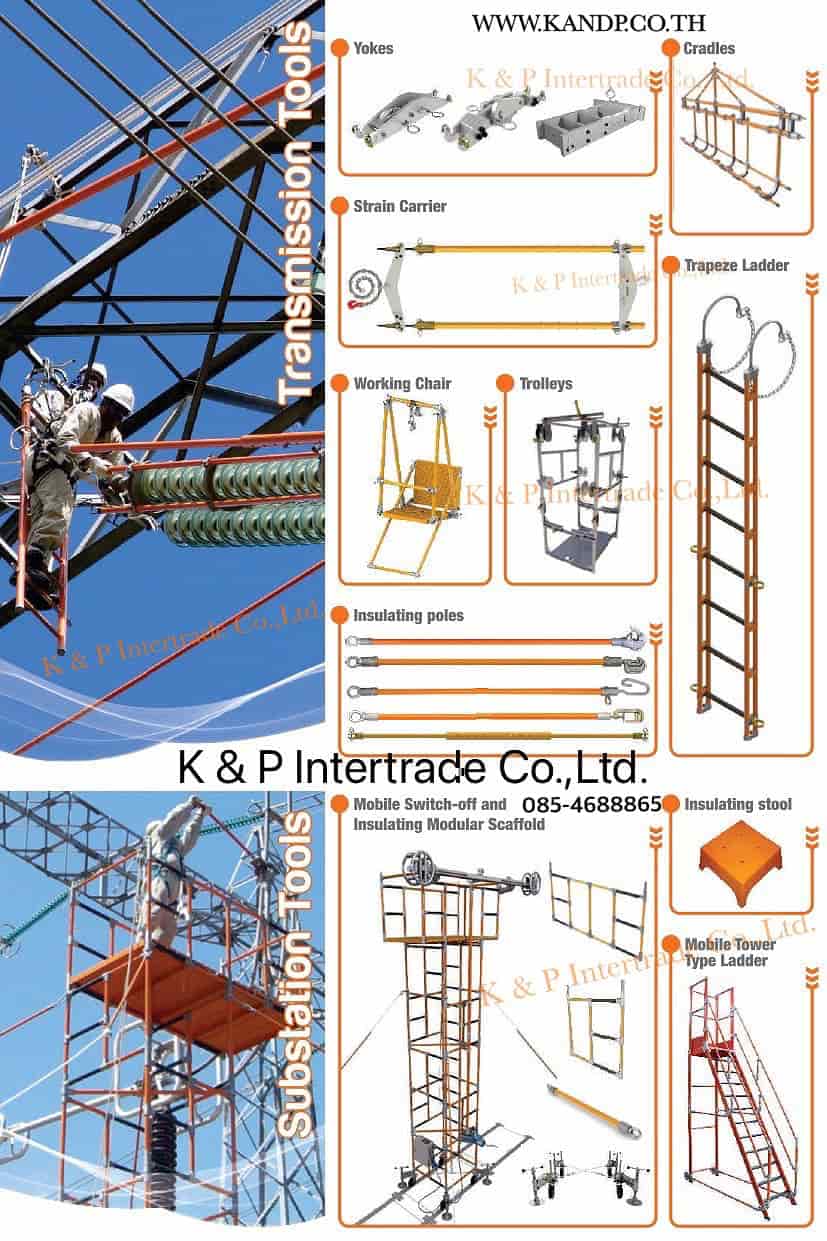

The great need to avoid undesirable power maintenance shutdowns required the development of safe techniques and practices for uninterrupted power supply, without negatively affecting generation, transmission, and distribution utilities. Not only financially, but also regarding how these utilities are seen by their consumers.

The numberless services to be performed in different voltage classes and different types of electrical installations, such as transmission lines, substations and distribution networks, have encouraged the development of tools, as well as unique and situationspecific working methods, depending on the type and location of the tasks to be performed and even the criteria defined by each utility.

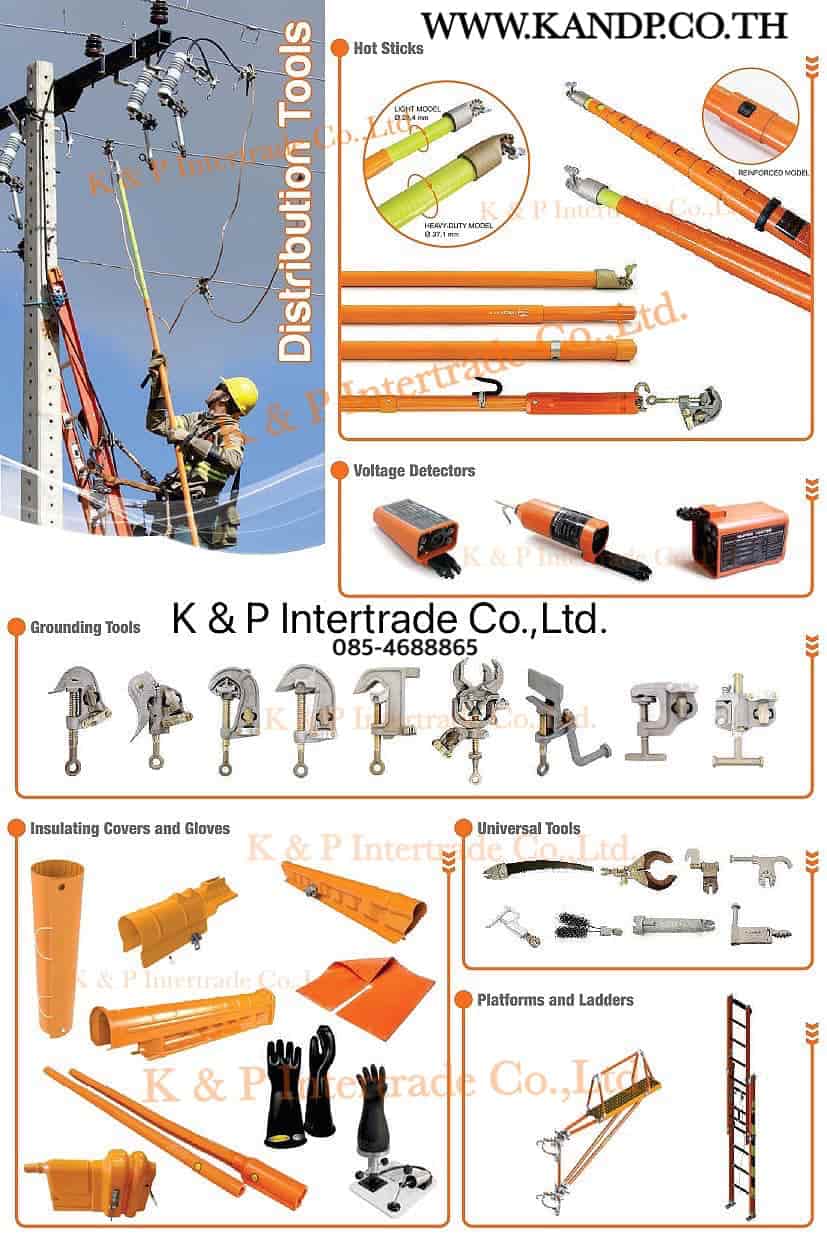

Now the electrical system has three hot line working methods that can be applied in many voltage classes, provided electrician teams are properly trained and have proper tools, personal protective equipment (PPE), and collective protective equipment (CPE). 1° METHOD - HOT STICK METHOD

In this method, the first to be developed, the electrician performs operations using tools attached to the end of a insulating stick. This method is designed for work on all voltage classes.

For voltages up to 69 kV, where phase distances are shorter, conductors are removed from their original position by means of support poles, clamps etc.

The entire hot line toolkit is designed to make it easier for electricians to move around structures with total safety.

Refine Search

เครื่องมือช่างไฟฟ้าแรงสูง Hot line Equipment RITZ บลาซิล

เครื่องมือช่างไฟฟ้าแรงสูง Hot line Equipment RITZ นำเข้าจากประเทศบลาซิลGrip-all Clampstick 8 Ft..

฿0

ไม้ชักฟิวส์ แบบสไลด์ (6 ท่อน) ยาว 25 ฟุต RITZ Cat. No. VTT-1/6 พร้อมถุงหนังเทียม

ไม้ชักฟิวส์ แบบสไลด์ (6 ท่อน) ยาว 25 ฟุต RITZ Cat. No. VTT-1/6 พร้อมถุงหนังเทียม..

฿0

ไม้ชักฟิวส์ แบบสไลด์ (8 ท่อน) ยาว 10.59 เมตร RITZ Cat. No. VTT-1/8

ไม้ชักฟิวส์ แบบสไลด์ (8 ท่อน) ยาว 10.59 เมตร RITZ Cat. No. VTT-1/8..

฿0

สินค้าของเรา

ไม้ชักฟิวส์แรงสูง·เครื่องกำเนิดไฟฟ้า·รอกยกของ·ไม้ชักฟิวส์·ไม้ฉนวน·บันไดสไลด์·มีดปอกสาย·ชุดประกอบฉนวนค้ำยันสายไฟ·Ratchet and Coffing Hoist·LINGHTING ARRESTER 25-26 KV. 5kA. PREISE·Drop out Fuse Cutout Cover·Electrical installation equisment·WWW.KANDP.CO.TH·Cutout Bracket type ANSI TR202·K & P INTEKTRADE CO.LTD·Disconnecting Switch Barrier·Drop out 27 KV. 100.A 8kA "U-TAH"·Ratchet Cable Cutter· Insulator Cover·InsulatedHanger·Conductor Cutter with Insulated Handles·Conductor Cover 46 kv·Clamp stick grip all type ขนาด 8 ฟุต·Clamp Stick grip all type ขนาด 12 ฟุต·สว่านไร้สาย·ล้อวัดระยะทาง·ประแจบล๊อคไฟฟ้าไร้สาย (BRUSHLESS CORDLESS IMPACT WRENCH)·เทปวัดระยะชนิดโลหะ·ตู้แผงสวิตช์·ตู้เก็บเครื่องมือ·เครื่องอัดลมใช้มอเตอร์ไฟฟ้า·เครื่องมือบีบหลอดต่อสายไฮดรอลิค·เครื่องมือบีบคอนเนคเตอร์ แบบ H·เครื่องมือต่อสายลงดิน (Grounding Equipment)·เครื่องมือจับและดึงสาย (Wire Grip Come Along) Overall outside·เครื่องดึงสาย (Coffing Hoist)·อุปกรณ์ระบบไฟฟ้า·สวิตซ์ตัดตอนแรงสูง·หางปลา·หลอดต่อสาย·สลักเข้าปลายสาย·พีจีคอนเนคเตอร์·ฉนวนป้องกันไฟฟ้าลัดวงจร·ฉนวนครอบล่อฟ้า·เครื่องมือช่างไฟฟ้าอุตสาหกรรม·เครื่องมือไฮดรอลิก·เครื่องมือแบตเตอรี่ไร้สายดิสคอนเนคติ้งสวิตซ์แบริเออร์·ฉนวนครอบบุชชิ่ง·ตาข่าย·แผ่นอลูมิเนียม·ฉนวนครอบดรอปเอาท์ฟิวส์·หนามป้องกันสัตว์·อุปกรณ์ระบบไฟฟ้า·หม้อแปรง·Grip-all Clamp Stick·High Voltage Equipment·อุปกรณ์ติดตั้งระบบไฟฟ้าแรงสูง Pole Cover·Conductor Cover·Drop out cover·Telescopic Hot Stick·สินค้ารอกดึงสายไฟฟ้า R.I.K (Made in Thailand ผลิตสินค้าในไทย)·ไฟฟ้า·ROADMAPTOSTRONGGRIDLV·แคล้มป์สติ๊ก·ClampStick·เชือกใยยักษ์·เชือก Blue Polypopelene Handline 16mm·KNIPEX·เครื่องตรวจจับแรงดันไฟฟ้า·UNI·สายกันตก·UNI9103·เข็มขัดปีนเสา·YQK·SME·ขายดี·หมวกปีกรอบ·KPIR DISCONNECT STICK·หมวกนิรภัย S-Guard·MSA V-Gard full brim·คีมตัดสาย·คัทเตอร์ตัดสาย·CableCutter·คีมตัดลวดเหล็ก·คัทเตอร์เฟืองทด·คัทเตอร์ตัดสายเคเบิ้ล·คีมย้ำ·คีมบีบ·แคล้มป์สติ๊ก·KANDP·Milwaukee·CHANCE·RITZ·KUDOS·ZUPPER· FLUKE·Klauke Hydraulic Crimp Tool·Google·

Official Facebook Page

เนื้อหาส่วนนี้อาจไม่แสดงกรณีใช้ผ่านมือถือบางรุ่น ทางบริษัทฯ ขออภัยในความไม่สะดวก